Click here for more products

Click here for more products

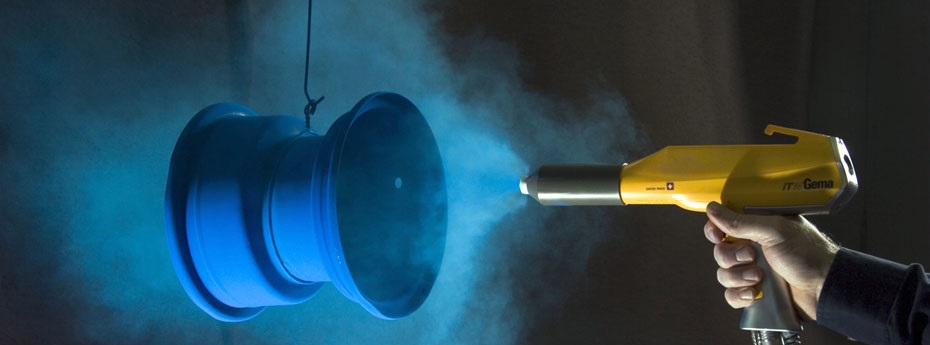

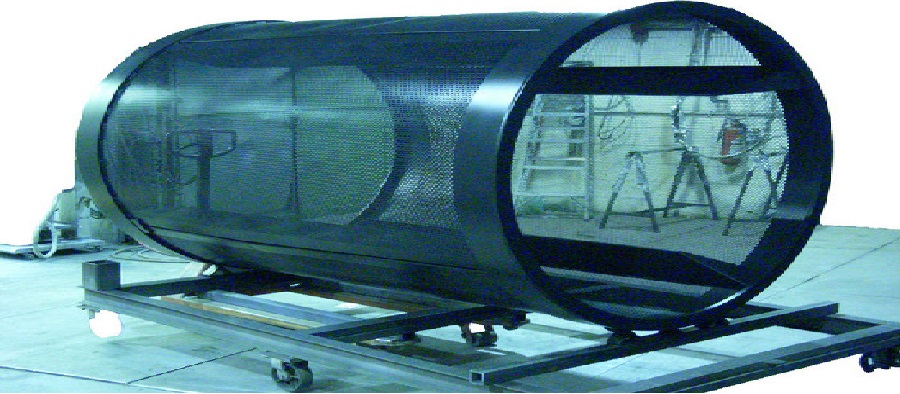

PTFE Coatings

Polytetrafluoroethylene PTFE coating uses a two-coat (primer/topcoat) system. These products have the highest operating temperature of any fluoropolymer and have extremely low coefficient of friction, fair abrasion resistance and good chemical resistance. A PTFE coating can withstand a maximum use temperature of 600°F. This coating is typically applied to a thickness of 1-3 mils. Metal Coatings offers a wide range of coatings to meet your application needs including FEP coatings, which have similar characteristics of PTFE coatings. Both PTFE and FEP coatings are food grade coatings. We provide the TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE. HVM SURFACE ENGINEERING provides the TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE.

Polytetrafluoroethylene PTFE coating uses a two-coat (primer/topcoat) system. These products have the highest operating temperature of any fluoropolymer and have extremely low coefficient of friction, fair abrasion resistance and good chemical resistance. A PTFE coating can withstand a maximum use temperature of 600°F. This coating is typically applied to a thickness of 1-3 mils. Metal Coatings offers a wide range of coatings to meet your application needs including FEP coatings, which have similar characteristics of PTFE coatings. Both PTFE and FEP coatings are food grade coatings. We provide the TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE. HVM SURFACE ENGINEERING provides the TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE.

| Elongation (ASTM D1457) | 300-500% |

| Impact Strength (ASTM D256) | 3.5 ft-LB/in |

| Hardness (ASTM D2240) | 50-65 HB (shore D) |

| Abrasion Resistance (Tabor) | 12 mg |

| Coefficient of Friction (ASTM D1894) | .12 -.15 static, .05 -.10 dynamic |

| Dielectric Strength (ASTM D149) | 450 volts per mil |

| Use Temperature | 600°F max |

| Melting Point | 625°F |

| Thermal Conductivity | 1.7 BTU-in/h-ft 2-°F |

| Chemical Resistance (ASTM D543) | Excellent |

| Salt Spray Resistance (ASTM B117) | Fair |

| Water Absorption (ASTM D570) | < .01% |

Fluoropolymer Coatings

Fluoropolymer ceramic composite coatings are blends of high performance resins and fluoropolymer lubricants. These coatings are a superior dry film lubricant that produce a smooth, hard, slick coating and provide excellent corrosion and chemical resistance. Other benefits of fluoropolymer coatings include reduced friction, resistance to galling, non stick, non wetting, electrical resistance and abrasion resistance. Fluoropolymer coatings are applied to fasteners and various OEM components to provide a longer life before replacement.

HVM SURFACE ENGINEERING provides TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE.

Fluoropolymer ceramic composite coatings are blends of high performance resins and fluoropolymer lubricants. These coatings are a superior dry film lubricant that produce a smooth, hard, slick coating and provide excellent corrosion and chemical resistance. Other benefits of fluoropolymer coatings include reduced friction, resistance to galling, non stick, non wetting, electrical resistance and abrasion resistance. Fluoropolymer coatings are applied to fasteners and various OEM components to provide a longer life before replacement. HVM SURFACE ENGINEERING provides TEFLON COATING JOB WORK IN BANGALORE and make the Best TEFLON COATING JOB WORK IN BANGALORE.

| Tensile Strength (ASTM D1708) | 4000 - 5000 psi |

| Elongation (ASTM D1457) | 50% |

| Impact Strength (ASTM D256) | 13 ft - LB/ in |

| Hardness (ASTM D2240) | 60 - 90 HB (Shore D) |

| Abrasion Resistance (Tabor) | > 15 mg |

| Coefficient of Friction (ASTM D1894) | .15 -.35 static |

| Dielectric Strength (ASTM D149) | 1400 volts per mil |

PTFE Coatings

PTFE Coatings